Open-Cell: An Open-Source 3D Printable System for High-Throughput Cell-Free Screening

This project aims to produce an open source SLA printable system for high-throughput screening of cell-free enzymes and enzyme activity.

The Idea

One of the primary goals of synthetic biology is to use the components of biological organisms to produce valuable biochemicals from a stock of commodity substrates. In an effort to advance the progress of the field towards this goal, our team has developed a two-part project that combines the latest advancements in machine learning with microfluidics-based cell free screening assay technology. In the first part of the project, a Generative Adversarial Network (GAN) has learned how to generate a plausible reaction pathway between any two small molecule biochemicals. For each step in this pathway, a second GAN has learned to generate amino acid sequences that could plausibly catalyze each step in the reaction pathway in a cell-free environment. The second part of the project is to test the effectiveness of the algorithm in situ via a high efficiency open-source microfluidics device. This platform must be capable of expressing predicted enzymes, testing them against their substrates, sampling the product solutions for input into an LC-MS, chaining reactions together into pathways, and interfacing with high-throughput laboratory automation hardware such as an OpenTrons or a LabCyte Echo.

The Team

Mr Clayton Rabideau,

PhD Sutdent, Department of Chemical Engineering and Biotechnology, University of Cambridge

Mr Stefan Grossfurthner,

PhD Sutdent, Department of Plant Sciences, University of Cambridge

Project Outputs

Project Report

Summary of the project's achievements and future plans

Project Proposal

Original proposal and application

Project Resources

Progress on fabrication of the 3D-printable device

Figure 1: Process flow diagram illustrating basic design of the device. The upper section combines the components required for CFPS in a single reaction chamber. The lower section purifies newly synthesized protein using chromatography. 96 of these are multiplexed within a standard microplate footprint.

Summary

The aim of this project was to develop a robust 3D-printable device that could be used to increase the throughput of protein synthesis and purification via CFPS cell-free protein synthesis (CPS) and affinity chromatography, respectively. The device is composed of a CPS reactor that translates an input sequence of DNA into the corresponding protein, which is subsequently purified from the cell-free extract through a downstream affinity chromatography column (Fig. 1). It was designed to fit within a standard 96-well microplate footprint that could integrate into existing instruments and workflows. We have completed a prototype and conducted preliminary tests on liquid flow through the prototype. This has allowed us to identify aspects of the initial design that require improvement, such as the valve system employed to regulate flow through the device. We are currently in the process of implementing these improvements and designing experiments to further test functionality of the device.

Report and outcomes

The initial design specification for our device called for the multiplexing of 96 dual-stage reactors - each of which was composed of a CPS module and a protein purification module – within a 9 mm x 9 mm x 9 mm space (Fig. 2). The system was designed so that the flow of input buffers and reagents required for these modules could be regulated by an external peristaltic pump.

Figure 2: Diagram illustrating 3D design of the device.

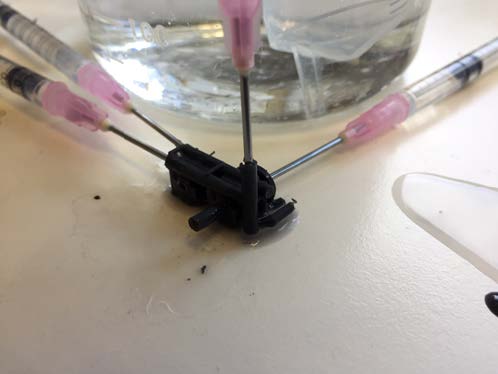

The device was printed in several stages using the Formlabs Form 2 UV photolithographic printer. The initial print demonstrated that the diaphragm valve design we employed to control liquid flow worked (Fig. 3A), however, the flexible resin material lacked structural integrity and developed cracks after several days of use (Fig. 3B). As a result, we increased thickness of the tubing, as well as the number and size of support structures. This increased the time until cracks developed but did not completely prevent their occurrence.

Figure 3: Pressure testing of an individual valve (left) and cracks in the walls of the valve after several days of testing (right).

We are therefore aiming to re-implement the soft valves using a different material. There are several designs reported in the literature that report success using a material similar to the Formlabs Clear Resin – we are currently working towards optimizing the valve using this type of resin. We have also initiated a collaboration with a second OpenPlant team to investigate open-source materials for implementing the chromatography column in the protein purification module of the device. Work on the protein purification module can be decoupled from work on the CFPS and conducted in parallel, so that development of the former will not be affected by the challenges we have faced with the valve design.

Follow on Plans

Once the new valve design has been optimised and the device is operational with CFPS buffer substitutes like water and glycerol, we will test the device by synthesizing common reporter proteins such as GFP and – in collaboration with our collaborators mentioned above the other team – purify them using a variety of different chromatography column materials. Once this has been carried out, we plan to publish the CAD design files to the DocuBricks site and the code required to operate the pumping mechanism to an open repository on GitHub, both under permissive licenses.